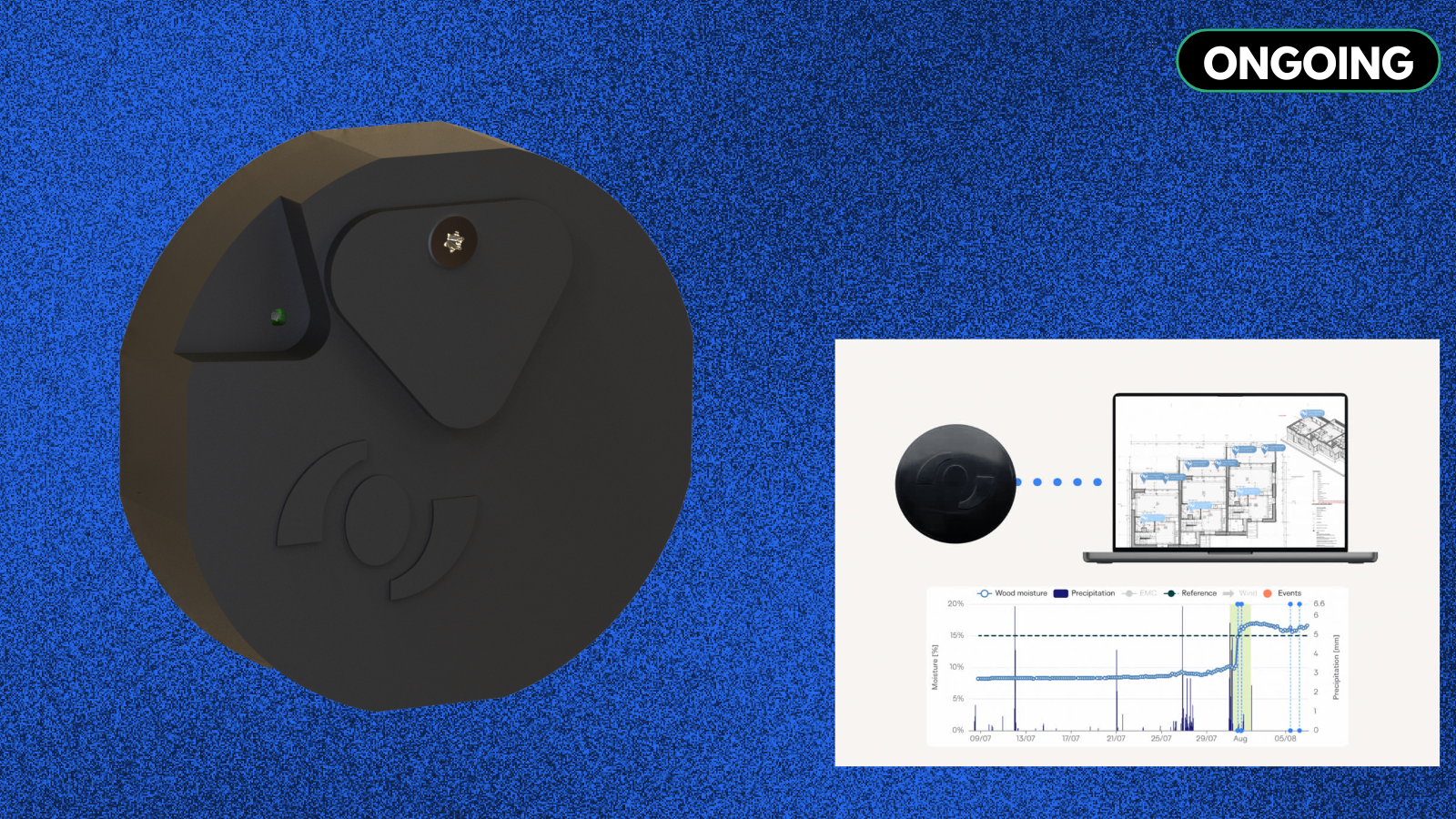

Tector G2W/G2F Series

🎯 Product Brief

Tector’s moisture management solution is an intelligent IoT-enabled system designed to detect, monitor, and prevent moisture-related problems in buildings throughout design, construction, and long-term operation. By combining wireless moisture sensors, real-time analytics, AI-powered alerts, and a user-friendly dashboard, Tector empowers building owners, contractors, and facility managers to make proactive decisions that protect structural integrity, reduce unnecessary costs, and support sustainability goals. This proactive approach eliminates reliance on manual inspections and enables data-driven quality assurance across a wide variety of construction types and environments.

💼 What I Worked On

I led the development of Tector’s second-generation flagship IoT sensor platform, the Gen 2 series (G2W / G2F); another project I am particularly proud of due to its technical complexity, long-term impact, and end-to-end ownership.

As technical lead, I was responsible for the complete product lifecycle, guiding the sensor from early prototype through design, validation, certification, and ultimately mass production. My responsibilities spanned hardware and firmware architecture, component selection, sourcing and supply-chain strategy, testing and validation, regulatory compliance, and production readiness.

A core focus of the project was designing a sensor platform capable of operating reliably for up to 25 years. This required meticulous optimization of both electronics and firmware, extensive lifetime testing, and comprehensive documentation. The result was a rugged, user-friendly, and interactive sensor designed for long-term deployment in demanding building environments.

I coordinated closely with a Poland-based contract manufacturer (EMS) to establish scalable production workflows. To support manufacturing quality and traceability, I designed and built a custom PCBA-level test jig from scratch, enabling automated testing, full production traceability, and accurate tracking of defects and process deviations throughout manufacturing.

In parallel with development and production efforts, I also took on a customer-facing role, working directly with clients to support product selection, installation guidance, and diagnostic troubleshooting in real-world deployments.

Through strategic sourcing and supplier diversification, I helped introduce production redundancies and alternative suppliers, reducing overall production costs by approximately 30% while improving resilience.

I also played a key role in securing critical international certifications, including EMC, CE, FCC, IC, and RCM, ensuring the product’s readiness for global markets.

⚙️ Technologies I Used

📟 Core Hardware Stack

- ATSAMD21 (previous generation)

- Seeed LoRa E5

- Sensirion SHTxx series

👨🏻💻 Software Stack

- C

- Python

- Pytest

- Doxygen

- Git

- GitHub

- SEGGER JLink

- SEGGER Ozone

- SEGGER SystemView